How to Analyse Automotive Test Data

How to analyse automotive test data. At Vehicle Testing Solutions (VTS), we help engineers turn complex logs and system behaviour into clear insight.

VTS First Automotive Testing Expo Stuttgart 2025

VTS First Automotive Testing Expo Stuttgart 2025

VTS Attends the 3rd UK Future Mobility Trade Mission in Türkiye

VTS Attends the 3rd UK Future Mobility Trade Mission in Türkiye

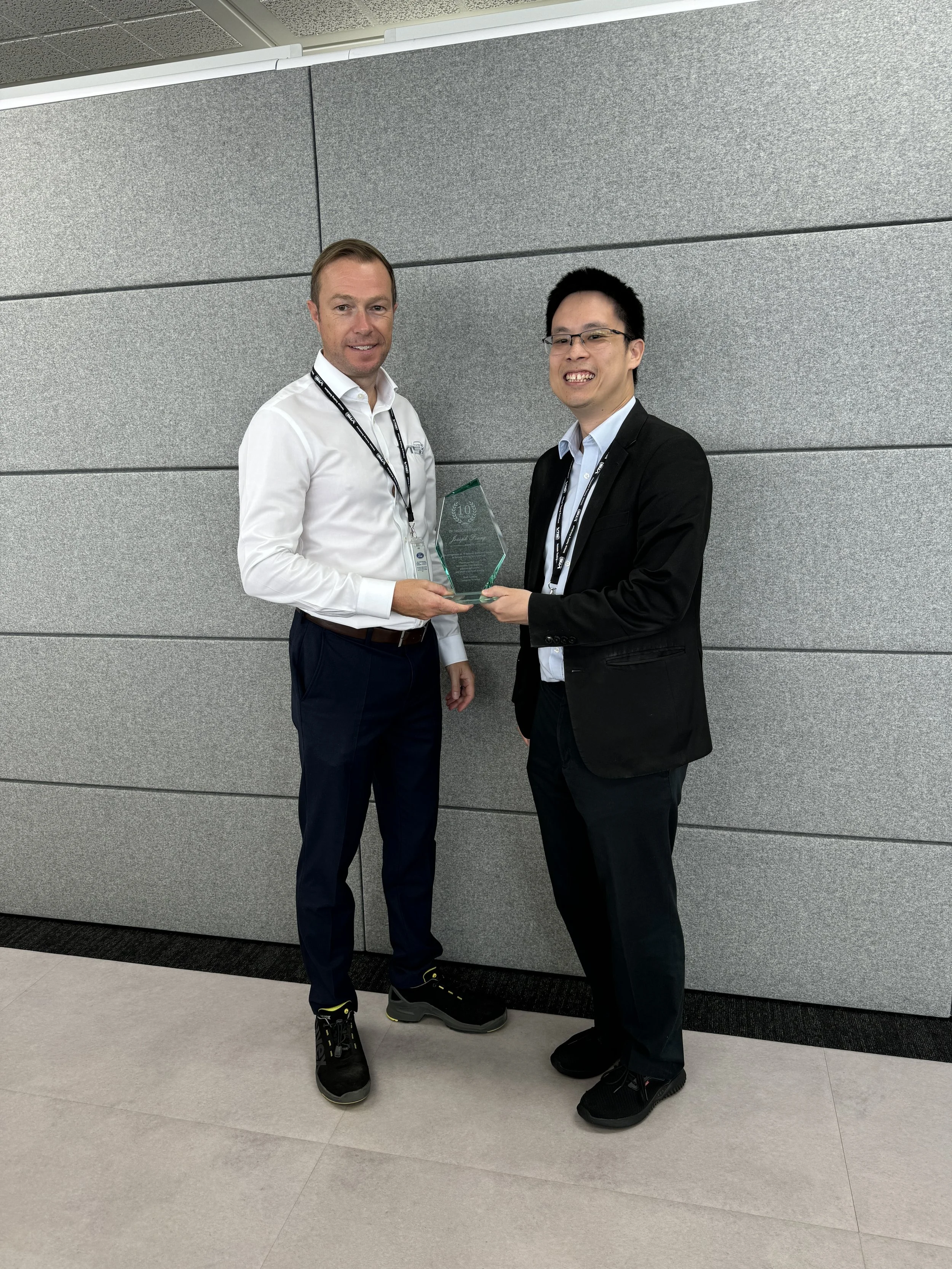

JLR Supplier Engagement Day-A Success

JLR Supplier Engagement Day-Vehicle Testing Solutions